EPOXY AND POLYASPARTIC

FLOORING | Idaho

Magic Valley | Pocatello | Twin Falls | Mountain Home | Burley | Jerome | Rupert

Hailey | Gooding | Ketchum | Wendell | Bellevue | Shoshone | Glenns Ferry | Fairfield

Epoxy flooring is the perfect blend of durability, style, and functionality for both residential and commercial spaces. At ORR Floor Care, we specialize in transforming concrete surfaces into sleek, low-maintenance flooring that stands the test of time. We bring expert craftsmanship and utilize high-quality epoxy coatings to deliver floors that are visually stunning, cost-effective, and built to last. Whether you're upgrading your garage, enhancing your warehouse, or creating a unique look for your showroom, epoxy flooring offers unmatched beauty and performance.

OUR EPOXY COATING SERVICES

At ORR Floor Care, we offer a comprehensive range of epoxy flooring services tailored to meet the unique needs of homes, businesses, and industrial facilities in Idaho. Whether you're looking to enhance your residential space with a sleek and durable finish, upgrade a commercial property for increased durability and style, or create a tough, functional surface for an industrial setting, we have the expertise to deliver stunning results that last. We utilize high-quality epoxy coatings and employ expert craftsmanship to transform your concrete floors into beautiful, low-maintenance, and long-lasting assets.

RESIDENTIAL

Epoxy flooring is a stylish and practical choice for homeowners in Idaho. It offers a durable and easy-to-clean surface that can withstand the demands of everyday life. Whether you're looking to transform your garage into a functional workspace, add a touch of modern elegance to your basement, or create a unique and eye-catching floor in your living room, epoxy flooring provides a long-lasting and attractive solution.

COMMERCIAL

In commercial settings, epoxy flooring offers a range of benefits. Its durability and resistance to heavy foot traffic, chemicals, and stains make it ideal for businesses such as retail stores, warehouses, and workshops. Epoxy flooring can enhance the appearance of your commercial space, create a safer and more hygienic environment, and contribute to a positive customer or employee experience.

INDUSTRIAL

For industrial applications, epoxy flooring is the ideal choice. Its exceptional durability, resistance to chemicals and heavy machinery, and easy-to-clean surface make it perfect for demanding environments. From manufacturing plants and warehouses to laboratories and food processing facilities, epoxy flooring provides a robust and long-lasting solution that can withstand even the toughest conditions.

STYLE OPTIONS

FLAKE EPOXY

This type of epoxy flooring incorporates decorative flakes (often vinyl chips) into the epoxy coating. These flakes come in various colors and sizes, creating a unique and attractive speckled appearance. Flake epoxy flooring is highly durable, resistant to abrasion and chemicals, and easy to clean. It's a popular choice for garages, workshops, and other areas where both durability and aesthetics are important.

SOLID COLOR EPOXY

As the name suggests, solid color epoxy creates a uniform, seamless, and visually appealing finish. It's available in a wide range of colors, allowing you to customize the look of your floor to match your desired aesthetic. Solid color epoxy is a popular choice for both residential and commercial applications, offering a sleek and modern look.

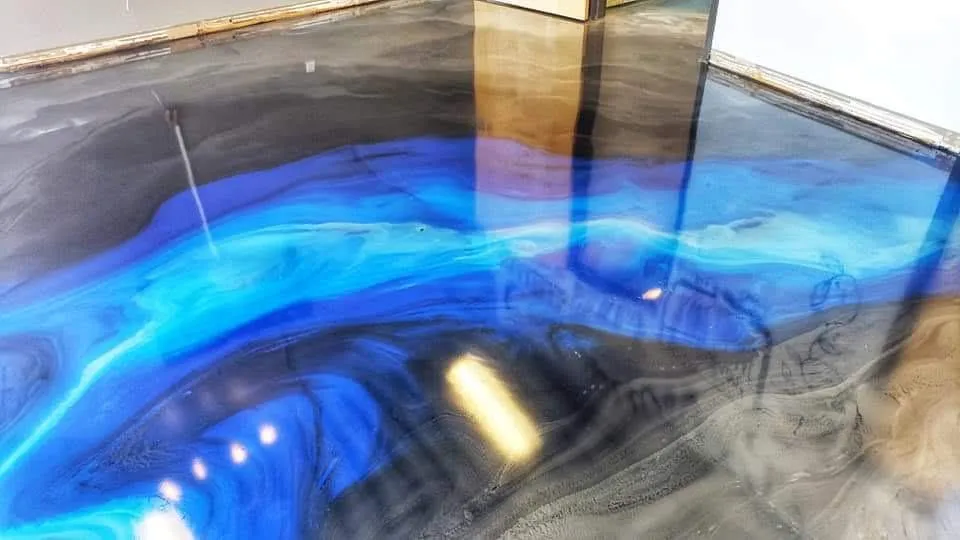

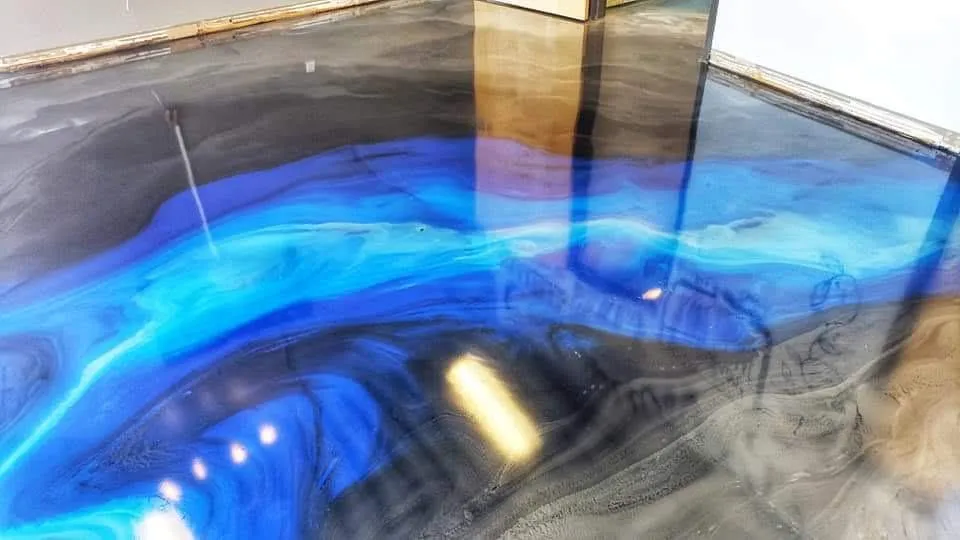

METALLIC EPOXY

This high-end option incorporates metallic pigments into the epoxy coating, creating a unique, shimmering effect that resembles liquid metal. Metallic epoxy floors are known for their luxurious appearance and are often used in high-end showrooms, retail spaces, and other areas where visual impact is paramount. While more expensive than other epoxy options, metallic epoxy offers a truly unique and stunning finish.

Why Choose Orr Floor Care for Your Next Epoxy Flooring Project?

Your floors are more than just surfaces; they're an integral part of your home or business. At Orr Floor Care, we believe in creating epoxy floors that are not only beautiful but also incredibly durable and built to last.

Rooted in the Magic Valley

As a locally owned and operated company, we're deeply invested in our community. We understand the unique needs of Idaho residents and businesses and are committed to delivering exceptional service to our neighbors.

Years of Experience, Proven Expertise

With years of experience in the flooring industry and a dedicated focus on epoxy applications, our team possesses the knowledge and expertise to handle any project, from residential garages to demanding commercial spaces. We utilize proven techniques and the highest quality epoxy coatings to ensure a flawless and long-lasting finish.

A Promise You Can Trust

We prioritize integrity and craftsmanship in every project. We don't cut corners and always strive to exceed your expectations. Our commitment to quality is backed by a 5-year warranty.

Start With Confidence

Choose Orr Floor Care for your epoxy flooring needs and experience the difference. We're dedicated to providing exceptional service and creating floors that will enhance your property for years to come. Contact us today for a free consultation.

STAINED POLISHED CONCRETE

What are the different types of flakes used in flake epoxy flooring?

Flake epoxy flooring utilizes a variety of materials for its decorative flakes, each offering unique visual characteristics and performance properties.

-Vinyl Chips: The most common type, vinyl chips come in a vast array of colors, sizes, and shapes. They are typically manufactured from durable vinyl polymers and offer a wide range of color options, from subtle earth tones to vibrant and playful hues.

-Quartz Flakes: Made from natural quartz, these flakes provide a more refined and sophisticated appearance. They offer a unique sparkle and can create a more luxurious feel compared to traditional vinyl chips.

-Metallic Flakes: Incorporating metallic pigments, these flakes add a shimmering, reflective quality to the epoxy floor. They create a stunning visual effect, particularly under certain lighting conditions.

Glass Flakes: These flakes offer a unique, translucent appearance and can create a shimmering, almost iridescent effect when incorporated into the epoxy coating.

How durable is flake epoxy flooring?

Flake epoxy flooring is renowned for its exceptional durability. The epoxy coating itself provides a robust barrier against abrasion, impact, and chemical spills. The embedded flakes further enhance durability by adding an extra layer of protection and minimizing the visibility of minor scratches. This makes flake epoxy an ideal choice for high-traffic areas such as garages, workshops, and commercial spaces. It can withstand heavy foot traffic, the impact of moving equipment, and exposure to a variety of chemicals commonly found in these environments.

Can flake epoxy flooring be customized?

Yes, flake epoxy flooring offers a high degree of customization to suit individual preferences and design aesthetics.

Color Selection: A wide range of flake colors and sizes allows for virtually limitless color combinations. You can choose from subtle earth tones, vibrant hues, and even metallic finishes to create a unique and personalized look.

Flake Broadcast Rate: The amount of flakes applied to the epoxy coating can be adjusted to achieve varying levels of coverage and visual texture. A denser flake broadcast creates a more pronounced and vibrant appearance, while a lighter broadcast results in a more subtle and understated look.

Custom Designs: In some cases, it's possible to incorporate custom designs or logos into the flake epoxy flooring by using specialized techniques and templates.

Is flake epoxy flooring suitable for all concrete surfaces?

While flake epoxy can be applied to most concrete surfaces, proper surface preparation is crucial for optimal results and long-lasting performance. The concrete must be structurally sound, clean, dry, and free from any cracks, chips, or loose debris. Surface

Preparation Steps: Typically involve thorough cleaning to remove dirt, oil, and contaminants. Grinding or shot blasting is necessary to improve surface profile and ensure proper adhesion of the epoxy coating. Any cracks or imperfections in the concrete will be repaired using appropriate fillers.

How do I clean and maintain flake epoxy flooring?

Flake epoxy flooring is relatively easy to clean and maintain, making it a practical choice for busy households and commercial environments.

Regular Cleaning: Regular sweeping and mopping with a mild detergent solution are usually sufficient to keep the floor clean and free of debris.

Stain Removal: For tougher stains, a gentle scrubbing with a soft-bristled brush and a mild cleaning solution may be necessary. Avoid using abrasive cleaners or harsh chemicals that could damage the epoxy coating.

Spills: Clean up spills promptly to prevent staining.

Can I apply flake epoxy flooring myself?

While DIY epoxy flooring kits are available, professional installation is highly recommended for optimal results.

Professional Expertise: Our experienced team possesses the expertise to ensure proper surface preparation, accurate application, and a flawless finish. This includes selecting the appropriate materials, mixing the epoxy components correctly, and achieving even coverage throughout the entire surface.

Quality Control: Professional installers can identify and address potential issues before they become problems, ensuring a long-lasting and durable floor.

Warranty and Support: Professional installations often come with warranties that provide peace of mind and protect your investment.

What are the potential drawbacks of flake epoxy flooring?

While flake epoxy flooring offers numerous benefits, it's important to be aware of potential drawbacks.

Surface Texture: The embedded flakes can create a slightly less smooth surface compared to solid color epoxy.

Deep Scratches: Deep scratches may expose the underlying concrete, potentially affecting the overall appearance. However, regular maintenance and proper care can minimize the risk of deep scratches.

Color Fading: Over time, some degree of color fading may occur, especially in areas exposed to direct sunlight.

How does flake epoxy flooring compare to other flooring options?

Compared to traditional concrete, flake epoxy flooring offers significantly enhanced durability, stain resistance, and aesthetic appeal. It provides a more attractive and easier-to-maintain surface while protecting the underlying concrete from damage.

Compared to other decorative flooring options such as tile or carpet, flake epoxy flooring is generally more affordable, easier to maintain, and more durable in high-traffic areas. It also offers a more seamless and integrated look, as there are no grout lines or seams to collect dirt and grime.

Can I use flake epoxy flooring outdoors?

While flake epoxy is primarily designed for interior applications, some specialized formulations are available for outdoor use. However, outdoor applications may require additional considerations, such as UV protection and resistance to extreme weather conditions.

Factors to Consider: Exposure to direct sunlight, rain, snow, and temperature fluctuations can affect the durability and appearance of the flooring. Consult with our experts to determine the most suitable type of flake epoxy for your specific outdoor application.

Will the colors of the flakes fade over time?

The color stability of flake epoxy flooring depends on several factors, including the quality of the flakes, the type of epoxy used, and exposure to sunlight.

High-Quality Materials: Using high-quality flakes and UV-resistant epoxy coatings can help minimize color fading.

Sunlight Exposure: Direct sunlight can accelerate color fading. Consider using window treatments or other measures to minimize direct sunlight exposure in areas with flake epoxy flooring.

Regular Maintenance: Regular cleaning and maintenance can help to preserve the vibrancy of the colors.

SOLID COLOR EPOXY FLOORING

What are the color options available for solid color epoxy flooring?

Solid color epoxy flooring offers a wide range of color options to suit various design aesthetics and personal preferences.

Classic Neutrals: Popular choices include various shades of gray, white, and black, which provide a clean, modern look and can complement a variety of interior design styles.

Earthy Tones: Browns, beiges, and greens offer a warm and inviting feel, creating a sense of natural harmony.

Vibrant Hues: Bold colors like red, blue, yellow, and green can add a vibrant and energetic touch to any space.

Custom Colors: In many cases, it's possible to create custom color blends to match specific design requirements or personal preferences.

Is solid color epoxy flooring suitable for high-traffic areas?

Absolutely! Solid color epoxy flooring is highly durable and well-suited for high-traffic areas.

Residential: Withstands the demands of busy households, including heavy foot traffic, pet activity, and the occasional dropped object.

Commercial: Ideal for retail stores, restaurants, offices, and other commercial spaces that experience high levels of foot traffic.

Industrial: Suitable for various industrial applications, including warehouses, workshops, and manufacturing facilities, where the flooring needs to withstand heavy machinery and equipment.

Can I use solid color epoxy flooring on my garage floor?

Yes, solid color epoxy is an excellent choice for garage floors.

Durability: It provides a durable and long-lasting surface that can withstand the impact of vehicles, chemicals, and other potential hazards commonly found in garages.

Easy Maintenance: Simple to clean and maintain, making it easy to keep your garage floor looking its best.

Aesthetics: Solid color epoxy can transform your garage into a more attractive and functional space, whether you're using it for vehicle storage, hobbies, or simply as an extension of your living space.

Is solid color epoxy flooring easy to maintain?

Yes, solid color epoxy floors are incredibly easy to maintain.

Regular Cleaning: Regular sweeping and mopping with a mild detergent solution are usually sufficient to keep the floor clean and free of debris.

Stain Resistance: Most epoxy coatings are highly resistant to stains from oil, grease, and other common household substances.

Easy to Clean Up Spills: Spills can be easily wiped up without causing damage to the flooring.

Can I apply solid color epoxy flooring over existing concrete?

Yes, solid color epoxy can be applied over existing concrete surfaces, provided they are properly prepared.

Surface Preparation: This typically involves thorough cleaning to remove dirt, oil, grease, and other contaminants. Grinding or shot blasting may be necessary to improve surface profile and ensure optimal adhesion of the epoxy coating. Cracks and imperfections in the concrete should be repaired using appropriate methods to create a smooth and even surface for the epoxy application.

How can I personalize the look of my solid color epoxy floor?

While solid color epoxy flooring offers a clean and minimalist aesthetic, there are still ways to personalize the look and create a unique design.

Color Selection: Choose from a wide range of colors to match your desired aesthetic and complement your existing décor.

Finish Options: Select from different finishes, such as high-gloss, satin, or matte, to achieve the desired level of sheen and reflectivity.

Inlays: Incorporate decorative inlays, such as company logos, custom designs, or even metallic accents, to create a unique and personalized look.

Is solid color epoxy flooring prone to chipping or peeling?

When properly installed by experienced professionals using high-quality materials, solid color epoxy flooring is highly resistant to chipping and peeling.

Proper Installation: Proper surface preparation, proper mixing of the epoxy components, and even application are crucial for ensuring a long-lasting and durable finish.

Material Quality: Using high-quality epoxy coatings with excellent adhesion properties minimizes the risk of chipping and peeling.

Maintenance: Regular maintenance, such as sweeping and mopping, helps to prevent dirt and debris buildup that can contribute to wear and tear.

Can I apply solid color epoxy flooring outdoors?

While some epoxy formulations are suitable for outdoor use, it's crucial to choose a product that is specifically designed for outdoor applications and can withstand exposure to UV rays, moisture, and extreme weather conditions.

UV Protection: Outdoor epoxy coatings often contain UV inhibitors to prevent fading and discoloration caused by sunlight exposure.

Moisture Resistance: Outdoor formulations must be resistant to moisture and humidity to prevent damage from rain, snow, and other forms of precipitation.

Temperature Fluctuations: The epoxy coating must be able to withstand extreme temperature fluctuations without cracking or peeling.

How does the cost of solid color epoxy flooring compare to other flooring options?

Solid color epoxy flooring offers excellent value for money.

Cost-Effective: It is generally more affordable than other high-performance flooring options such as tile, stone, or hardwood, while providing comparable durability and aesthetic appeal.

Long-Term Savings: The long-lasting durability and low-maintenance requirements of epoxy flooring can result in significant long-term cost savings compared to other flooring options that may require frequent repairs or replacement.

What are the potential drawbacks of solid color epoxy flooring?

While solid color epoxy flooring offers numerous benefits, it's important to be aware of potential drawbacks.

Slip Resistance: In some cases, solid color epoxy floors can become slippery when wet. This can be mitigated by choosing a textured finish or incorporating anti-slip additives into the epoxy coating.

Temperature Sensitivity: Extreme temperature fluctuations can cause some minor expansion and contraction of the epoxy flooring. However, this is typically minimal and should not significantly impact the performance or appearance of the floor. *

Repairing Damage: If the epoxy coating is damaged, repairs may be more challenging compared to some other flooring options. Professional repair is often recommended to ensure a seamless and long-lasting repair.

METALLIC EPOXY FLOORING

What makes metallic epoxy flooring unique?

Metallic epoxy flooring incorporates metallic pigments into the epoxy coating, creating a unique, shimmering effect that resembles liquid metal.

Metallic Pigments: These pigments are typically made from metals such as aluminum, copper, and bronze. They create a stunning visual effect that changes depending on the angle of light, adding depth and dimension to the floor.

Luxurious Appearance: Metallic epoxy flooring offers a truly luxurious and sophisticated appearance, elevating the look and feel of any space.

What are the different types of metallic finishes available?

Metallic epoxy flooring offers a wide range of finish options to suit various design aesthetics.

Classic Metallic: This classic finish creates a subtle, shimmering effect with a smooth and even appearance.

Pearl: Incorporates pearlescent pigments to create a soft, iridescent sheen.

Galaxy: Creates a mesmerizing, galaxy-like effect with swirling patterns and varying shades of metallic color.

Custom Finishes: Many epoxy flooring contractors can create custom metallic finishes to meet specific design requirements.

Is metallic epoxy flooring suitable for all applications?

While metallic epoxy flooring is suitable for a wide range of applications, it may not be the most practical choice for high-traffic, industrial environments where durability is the primary concern.

Ideal Applications: Metallic epoxy is ideal for high-end residential spaces, such as showrooms, entertainment rooms, and home offices. It also works well in commercial settings such as boutiques, luxury retail stores, and high-end restaurants.

Less Suitable for: High-traffic industrial applications where the flooring may be subjected to heavy machinery, harsh chemicals, or extreme wear and tear.

How is metallic epoxy flooring applied?

The application process for metallic epoxy flooring involves careful preparation and precise application techniques.

Surface Preparation: Thorough surface preparation is crucial to ensure optimal adhesion and a flawless finish.

Base Coat Application: A base coat of epoxy is applied to the prepared surface.

Metallic Pigment Application: Metallic pigments are then carefully broadcast or troweled into the wet epoxy base coat.

Topcoat Application: A clear topcoat is applied over the metallic layer to protect the finish and enhance its durability and shine.

What are the maintenance requirements for metallic epoxy flooring?

Metallic epoxy flooring requires regular cleaning and maintenance to maintain its appearance and durability.

Regular Cleaning: Regular sweeping and mopping with a mild detergent solution are usually sufficient to keep the floor clean and free of debris.

Avoid Abrasive Cleaners: Avoid using abrasive cleaners or harsh chemicals that could damage the metallic finish.

Protect from Sharp Objects: Avoid dragging heavy furniture or sharp objects across the floor, as this can scratch the metallic finish.

How does the cost of metallic epoxy flooring compare to other options?

Metallic epoxy flooring is generally more expensive than standard solid color or flake epoxy flooring.

Premium Materials: The use of high-quality metallic pigments and specialized application techniques contributes to the higher cost.

Labor Costs: The application process for metallic epoxy flooring may require more specialized skills and labor, which can also affect the overall cost.

Luxury Finish: Despite the higher cost, metallic epoxy flooring offers a truly unique and luxurious appearance that can significantly enhance the value and appeal of any space.

Can I apply metallic epoxy flooring myself?

Due to the specialized techniques and materials involved, it is strongly recommended to hire experienced professionals for metallic epoxy flooring installation.

Professional Expertise: Achieving a flawless metallic finish requires expertise in mixing the epoxy, applying the pigments evenly, and ensuring a smooth and consistent appearance.

Avoiding Mistakes: Improper application can lead to uneven coverage, air bubbles, or other imperfections that can significantly impact the final appearance of the floor.

Quality Control: Professional installers can ensure that the metallic epoxy flooring is applied correctly and meets the highest standards of quality and durability.

Does metallic epoxy flooring require any special lighting?

While not essential, the beauty of metallic epoxy flooring is often enhanced by appropriate lighting.

Lighting Considerations: Consider using directional lighting, such as spotlights or track lighting, to highlight the shimmering effects of the metallic pigments.

Natural Light: Natural light can also enhance the appearance of metallic epoxy flooring, but it's important to be mindful of potential UV damage and consider using window treatments to minimize direct sunlight exposure.

Can metallic epoxy flooring be used in all environments?

While metallic epoxy flooring is suitable for a wide range of applications, it may not be the most practical choice for high-traffic, industrial environments where durability and easy maintenance are the primary concerns.

Ideal Applications: Metallic epoxy is best suited for areas where aesthetics and visual impact are paramount, such as high-end residential spaces, showrooms, boutiques, and other commercial spaces with moderate foot traffic.

How can I maintain the appearance of metallic epoxy flooring?

To maintain the beauty and shine of metallic epoxy flooring, it's important to follow proper cleaning and maintenance procedures.

Regular Cleaning: Regular sweeping and mopping with a mild detergent solution are essential. Avoid

Abrasive Cleaners: Avoid using abrasive cleaners, harsh chemicals, or abrasive cleaning tools that could scratch or damage the metallic finish.

Protect from Sharp Objects: Be mindful of sharp objects that could scratch the floor surface.

Professional Maintenance: Consider periodic professional maintenance to address any minor issues and restore the original shine and luster.

GENERAL EPOXY FLOORING FAQs

What is epoxy flooring and how does it differ from traditional concrete?

Epoxy flooring is a multi-layered coating system applied over concrete surfaces. It's composed of a resin and a hardener that, when combined, create a strong, durable, and chemically resistant surface. Unlike bare concrete, epoxy flooring enhances the appearance, durability, and functionality of the concrete substrate.

What are the key benefits of choosing epoxy flooring?

Durability: Epoxy flooring is highly resistant to abrasion, impact, chemicals, and stains, making it ideal for high-traffic areas.

Easy Maintenance: It's easy to clean and maintain, requiring minimal effort to keep the floor looking its best.

Enhanced Aesthetics: Epoxy flooring offers a wide range of aesthetic options, from sleek solid colors to decorative flakes and stunning metallic finishes, allowing you to customize the look of your space.

Increased Safety: Epoxy flooring can be made slip-resistant, reducing the risk of falls and injuries.

Improved Hygiene: Epoxy flooring creates a seamless, non-porous surface that is easy to clean and sanitize, making it ideal for environments where hygiene is critical.

What are the different types of epoxy flooring available?

Solid Color Epoxy: Creates a smooth, uniform finish in a wide range of colors.

Flake Epoxy: Incorporates decorative flakes into the epoxy coating for a unique and visually appealing finish.

Metallic Epoxy: Features metallic pigments that create a shimmering, luxurious appearance.

Quartz Epoxy: Includes quartz flakes for a more natural and sophisticated look.

What is the role of proper surface preparation in the epoxy flooring process?

Proper surface preparation is absolutely critical for the success of any epoxy flooring project.

Thorough Cleaning: The concrete surface must be thoroughly cleaned to remove all dirt, dust, oil, grease, and other contaminants.

Moisture Testing: Moisture testing is essential to ensure the concrete substrate is dry and free from moisture. High moisture levels can cause adhesion problems and lead to premature failure of the epoxy coating.

Crack Repair: Any cracks or imperfections in the concrete must be repaired using appropriate methods to create a smooth and even surface.

Grinding/Profiling: Grinding or shot blasting the concrete surface can improve adhesion by creating a rougher surface for the epoxy to bond to.

What are the different methods of applying epoxy flooring?

Epoxy flooring is typically applied in multiple layers.

Primer Coat: A primer coat is applied to the prepared concrete surface to enhance adhesion and improve the overall performance of the epoxy coating.

Base Coat: The base coat provides the foundation for the topcoat and helps to ensure a smooth and even finish.

Topcoat: The topcoat provides the final finish and protects the underlying layers from wear and tear.

Decorative Elements: For flake epoxy or other decorative finishes, the flakes or other decorative elements are typically broadcast into the wet base coat.

How long does it take to install epoxy flooring?

Installation time varies depending on the size of the area, the complexity of the project, and the type of epoxy flooring being applied.

Typical Timeframes: For residential garages, installation can often be completed within a day or two.

Larger Projects: Larger commercial projects may take several days or even weeks to complete.

Curing Time: After application, the epoxy coating needs time to cure properly. Curing times can vary depending on the specific epoxy product and environmental conditions.

What are the maintenance requirements for epoxy flooring?

Epoxy flooring is relatively easy to maintain.

Regular Cleaning: Regular sweeping and mopping with a mild detergent solution are usually sufficient to keep the floor clean and free of debris.

Stain Removal: Promptly clean up spills to prevent staining. Most epoxy floors are resistant to stains, but it's best to address spills quickly.

Avoid Abrasive Cleaners: Avoid using abrasive cleaners or harsh chemicals that could damage the epoxy coating.

Can epoxy flooring be used in all environments?

Epoxy flooring is a versatile material that can be used in a wide range of environments, including residential, commercial, and industrial settings.

Residential: Garages, basements, kitchens, bathrooms, patios

Commercial: Showrooms, warehouses, retail stores, offices, restaurants, hospitals

Industrial: Factories, workshops, laboratories, clean rooms

Is epoxy flooring slip-resistant?

While epoxy flooring itself is generally slip-resistant, the level of slip resistance can vary depending on the type of epoxy used, the finish (glossy vs. matte), and the presence of any additives.

Slip-Resistant Additives: Anti-slip additives can be incorporated into the epoxy coating to enhance slip resistance in areas with high foot traffic or where safety is a primary concern.

Consult with Professionals: Discuss your specific slip resistance requirements with your flooring contractor to ensure that the chosen epoxy system meets your needs.

What are the potential drawbacks of epoxy flooring?

While epoxy flooring offers numerous benefits, it's important to be aware of potential drawbacks.

Temperature Sensitivity: Extreme temperature fluctuations can cause some minor expansion and contraction of the epoxy flooring.

Potential for Cracking: In some cases, improper installation or exposure to extreme temperature fluctuations can lead to cracking or delamination of the epoxy coating.

Repairs: Repairing damaged epoxy flooring can be more challenging than repairing some other types of flooring.